Medical products are becoming more complicated as there are more treatments and a higher level of customization. To remain competitive Fresenius must transform its manufacturing process and utilize the benefits auf AI, sensor technology, Big Data analysis and agile work processes. However, making such Digital Transformation is no easy task. Therefore, Fresenius has enlisted Crowdworx Digital Consulting services and tools to kick-off its innovation journey in a stable and effective manner.

Introduction

Fresenius Kabi is a world leader in high-quality medical products and services for hospitals. It operates production facilities worldwide with diverse and complex product portfolios to meet rising sophistication from its customers. Being part of the larger Fresenius corporation Fresenius Kabi is receiving and provides know-how to other business units of the corporation.

Issue

Fresenius Kabi is competing with Japanese, Israeli, European, and U.S. companies for providing highest quality at the best price. At the same time customers, e.g. hospitals, are demanding very broad product portfolio with a large number of product variations. With no room for production errors and very high medical production standards maintaining such a broad and deep product portfolio is making manufacturing more and more complex (see Figure 1).

Figure 1: High-level overview of the complexity of modern medical products manufaturing. Source: Crowdworx.

Solution

Fresenius Kabi enlisted Crowdworx to help transform its manufacturing process into a fully digital manufacturing process. Based on years of experience Crowdworx knew, that Digital Transformation cannot be prescribed top-down. The breadth and depth of change is just too big. Therefore, Crowdworx deployed one its proven co-innovation approach to Digital Transformation:

- Lead Department: A department is taking the lead to manage a digitization pilot project, to reduce decision times.

- Innovation Campaign: Employees world-wide are involved in the project to make sure this is the start of a bigger journey and not just an “elite” project.

- Fast Implementation: After having run the Innovation Campaign, the best employee ideas were piloted and tested, each with a team composed out of those who proposed the idea.

These pilot projects featured digital manufacturing innovations such as:

- Co-bots: Mix of standalone smart manufacturing robots and Co-Bot stations to allow for the best of both human understanding and machine efficiency,

- Full-sensor grid for collecting as much manufacturing micro data as possible,

- Built-in data feedback loops for constant training & improvement of the AI-powered manufacturing robots,

- Agile manufacturing planning processes and teams to respond to changes quickly with zero-error.

Impact

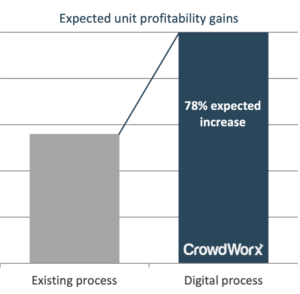

After having completed the first pilot projects the test results were evaluated. Based on the data from the pilots results estimations have been computed for a full-scale roll-out. As shown in Figure 2 the pilots have been quite amazing and are promising an almost 80% increase in profitability when rolled-out group-wide.

Some of the benefits achieved in the digital manufacturing pilots included:

- Higher speed: reduced process validation time and shorter time to market,

- Increased flexibility and efficiency: reduced stock level and transport time,

- Decreased failure rate: less defective products and less rework, increased customer satisfaction,

- Technology leadership: individualization of mass production, excellence in manufacturing of complex products,

- Digital culture: Focus on trial and error for fast realization and lessons learnt.

These and other benefits are helping Fresenius Kabi to now roll-out more digital innovations across their manufacturing plants and to achieve best-in-class product and service-level.

Project Lead

|

Stefan AltenbrunnHead of Client Services at Crowdworx, where he fuels innovation success for global leaders such as Bayer, Deutsche Bahn, Mercedes-Benz, Munich Re, and Qualcomm. Since 2011, he has been at the forefront of helping organizations turn ideas into measurable impact — driving adoption, scaling engagement, and ensuring innovation programs deliver real business value. With a proven track record in client success and business growth, he helps companies supercharge their innovation through idea pipeline development, breakthrough program expansion, and innovation culture building. |

About Crowdworx

Crowdworx® is the leading integrated software and consulting provider for all aspects of Idea and Innovation Management. With locations in Berlin and Poznan, we help our customers in numerous regions of the world with an excellent and comprehensive product and service portfolio for small and medium-sized businesses as well as corporate clients.